Qualified welders only

Qualified welders only

Qualified welders only

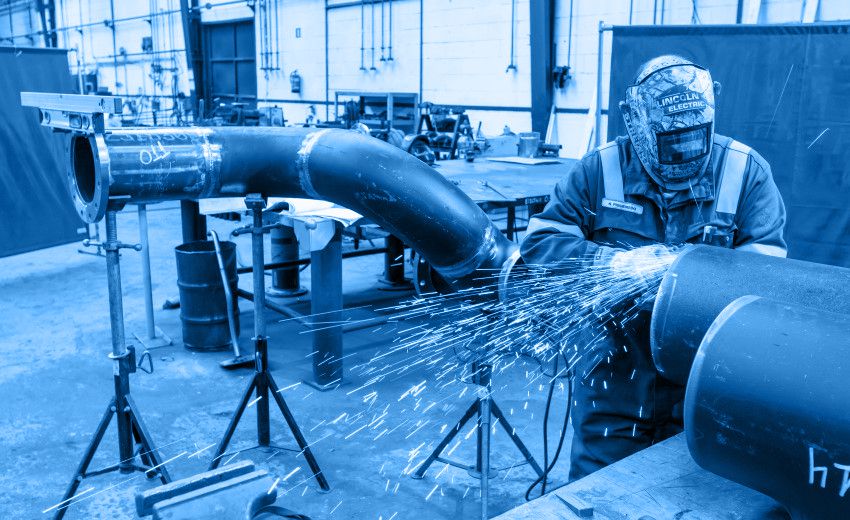

All welding at Niron Staal is done by qualified and, usually, internally-trained welders. The risk-assessment procedures of insurance companies often demand that the integrity of a structural weld is tested before it can be covered. QC Marine NDT Services has been working with Niron for the last three years.

Production of mega-constructions for heavy industry and the maritime market, such as the offshore industry, relies extensively on a delicate and careful approach to welding. These constructions need to be absolutely solid because they often have to support loadings of many tonnes. Safety is, of course, a priority for those working on these constructions and the engineers and the welders are always conscious of this, but the requirements of the insurance companies must also be taken into account. “They are very demanding where the welding process is concerned,” says Leo van der Marel, Sales Manager at QC Marine NDT Services. “Disasters could happen if the welds are not done properly and damage claims would be enormous, let alone the risk of people getting injured - or worse. So everybody involved is aware of a huge responsibility to make the constructions as safe and solid as possible.”

QC Marine is part of WRS Marine, a company that started twenty years ago in the Rotterdam area, providing services and products to the maritime market, such as inspecting vessels and their hulls for insurance purposes. The start of QC Marine five years ago was a logical step after so many years of experience with safety and sustainability issues. Leo van der Marel: “We use several non-destructive testing methods to determine the integrity of a material, component or structure. NDT does not harm, stress or destroy the test object. To achieve this goal we use methods like ultrasonic testing, magnetic particle testing, liquid penetration testing and eddy-current testing. And, not to forget, the use of a good pair of eyes.”

Whenever it is necessary, a team of specialists arrives at Niron’s construction hall to test the weld integrity. “We have to ensure that there are no imperfections, porosities or other welding errors. For the last three years we have been contracted to Niron as well as their sister company Shipdock and we have even got our own office in their yard, directly above Niron’s construction hall; in the first place for direct assistance within the yard and, secondly, to provide a base for our services to other industries in the province of Noord-Holland.”