New Floor type milling machine

New Floor type milling machine

New Floor type milling machine provides high cutting capacity and precision for Niron Staal Amsterdam

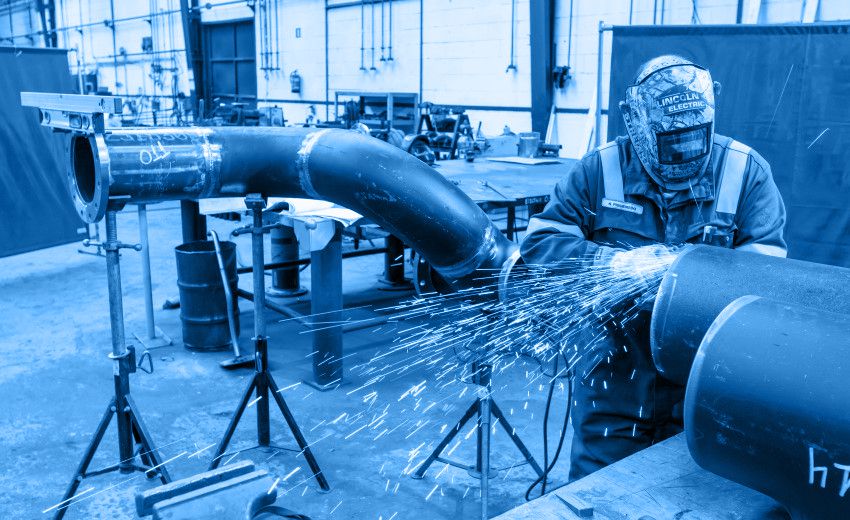

On the 16th of October Niron Staal Amsterdam, part of Damen Shiprepair & Conversion, opened its doors for what was called the ‘Grand Start’ of their latest addition to the fleet, an Soraluce FS 8000 floor type milling machine. The adjective ‘Grand’ isn’t an exaggeration: with an 8000mm X-axis and a large machining capacity the machine is perfect for large-scale constructions, which can be performed in a single piece production or in small series.

The acquisition reaffirms that the Dutch market for large milling machines, although modest, is growing.

Industrial sectors involving precise machining of heavy-constructions such as ship repair and maintenance, equipment manufacturing and the oil & gas industry are doing reasonably well. This reflects in the increasing purchases of new and used boring mills, carousel banks and large milling machines, including the ‘floor type’ version. The term ‘floor type’ refers to the way in which the movements are housed in the machine. In smaller machines the movements are housed in the table (table type) and in larger machines its housed in the column (floor type). Within the Soraluce the column moves over its slide while the movements in the Y- and Z- direction is performed by the spindle casing.

?

?

“We already owned a new Zayer milling machine for the machining of large constructions”, says Bob van der Moolen Manager Machineshop. “The Soraluce is a completely overhauled used machine, we ran into it during the Es & Es metalwork exhibition when we were looking for a good milling machine to accommodate peaks in our capacity. We’re now using the Zayer for more complex work, because of its diversified tool storage, whilst the Soraluce is being used for slightly simpler work. The Soraluce is equipped with a swivel head which is rotatable in increments of 2.5°.”

The 68-ton machine could only be placed with adjustments to the foundation, which formerly was used for a Scharman boring mill from 1956. The allocation of milling jobs on the two machines according the described formula works excellent. The Soraluce is mainly used for the machining of large crane parts, up to 8 meters long rail sections and heavy plates that are to be fitted with bevels. By applying the oblique profiles under various angles, the large machining capacity really sets a standards as there are no further requirements on the precision and surface quality.

With the FS series Soraluce has placed a machine type in the market that combines precision over long term productivity. The one used at Niron Staal, not the newest from the series, still perfectly meets the specifications. The lower gravity center of the machine guarantees, with other structural aspects, high stability. Soraluce indicates that this guarantee results in the possibility to save on the foundation costs, which is Niron Staal experienced by being able to install its machine at floor level. Besides saving in costs it also simplifies the operation, clamping of large constructions and maintenance.

Stability and thus the precision are further enhanced by the combined guiding- and damping system with cylindrical roller bearings on each axle and by the self-developed Soraluce hydrostatic damping elements. These elements between the bearings eliminate any vibration during machining. Other advantage contain high dynamics, minimal maintenance, less heat and grease. The X-axis is driven by two servomotors, two gearboxes and two double rack-and-pinion. The vertical and transverse axes are driven by pre-tensioned ball screws.