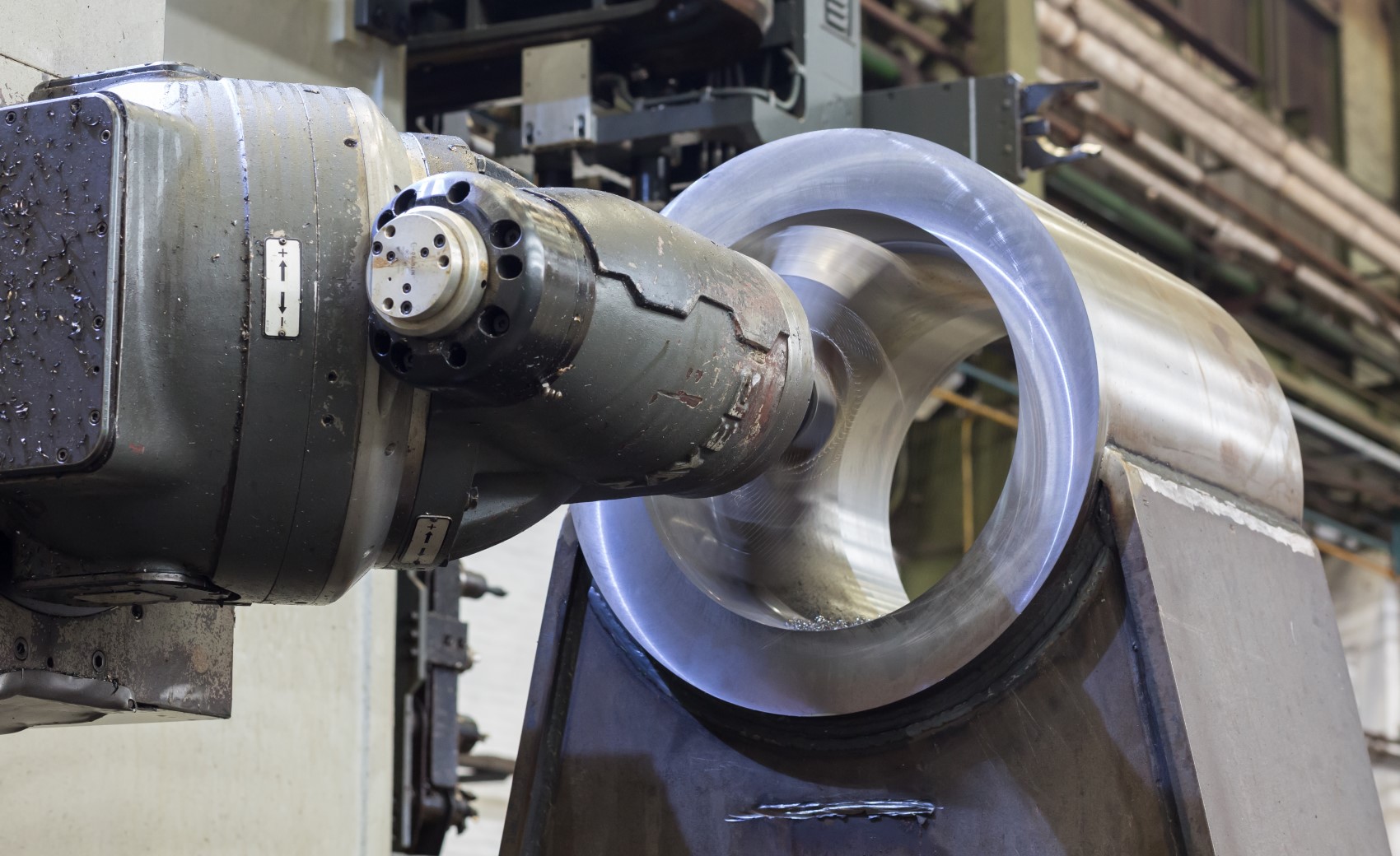

Machining

Perfection in Machining

Niron Staal operates a fully equipped machine shop including medium and large size CNC boring and milling machines, lathes and carrousels. A surface area of 5.000 m2 in combination with a lifting capacity of max. 150T allows us to have an optimal and spacious arrangement of the machinery and creates the ability to maneuver and place large constructions and components on the machines. Niron Staal is specialised in the machining of one-offs and small series but can also handle large series and recurring pieces. Our skilled employees provide short communication lines and will put their own practical expertise in place to advise our customer how to get the best result possible.

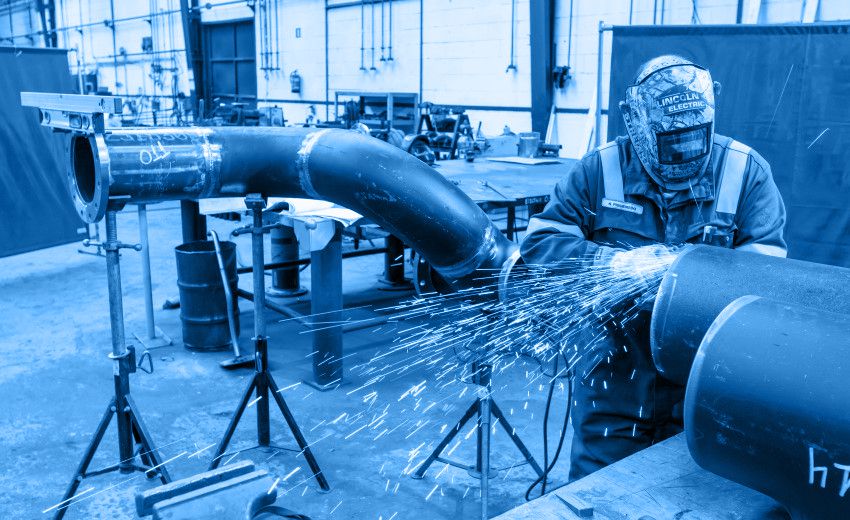

With the utmost precision and according to the customers drawing and specifications, we work according to the tolerances in place. Having multiple disciplines standby, Niron Staal is able to deliver cross-channel projects throughout the company. The three departments, Steel construction, Machining and Piping are able to complement each other and provide a total solution package.

Machining characteristics

Characteristics of machines.

| Horizontal X-as | Vertical Y-as | Spindel Z-as | Turning Table | |||

|---|---|---|---|---|---|---|

| Sacem | Horizontal boring machine | CNC | 5000 | 3000 | 600 | Square 1.4 x 1.6 m |

| Zayer 30 KCU | Vertical milling machine | CNC | 8000 | 2500 | 1500 | Square 2 meter |

| Soraluce FS8000 | Vertical milling machine | CNC | 8000 | 2500 | 1250 | Round 2 meter |

| Soraluce TR3500 | Vertical milling machine | CNC | 3500 | 1500 | 1200 | |

| Soraluce TRK3500 | Vertical milling machine | CNC | 3500 | 1500 | 1200 | Square 1 m |

| Pegard | Horizontal boring machine | CNC | 2400 | 2000 | 1200 | |

| Table diameter | Turing diameter | Working Hight | |||

|---|---|---|---|---|---|

| Dorries | Carousel Lathe | CNC | 1600 | 2100 | 1830 |

| Schiess | Carousel Lathe | Conventional | 1600 | 1650 | 1250 |

| Schiess | Carousel Lathe | Conventional | 2000 | 2270 | 1500 |

| Turning diameter | Hight above support | Center distance | |||

|---|---|---|---|---|---|

| Poreba | Lathe | Conventional | 2000 | 1600 | 8000 |

| VDF | LatheLathe | Conventional | 680 | 445 | 6000 |

| VDF | Lathe | Conventional | 520 | 300 | 3000 |

Expertise and Experience

Throughout the years and from the beginning onwards Niron Staal has gained the experience and trust in the machining of heavy-duty construction with high precision, having a large national and international customer base in heavy-duty industrial markets, the maritime industry, offshore, crane construction, dredging and construction companies. The type of constructions are wide-ranging and vary from tram rails to pedestals to skyscraper steel components and steel bevels to rudders and tail shafts.

For previous experiences and projects, please check our news section.